We Specialize In

Panels, Brackets, Enclosures, Internal Sheet Metal Components, and Multiple Part Assemblies.

Our Services

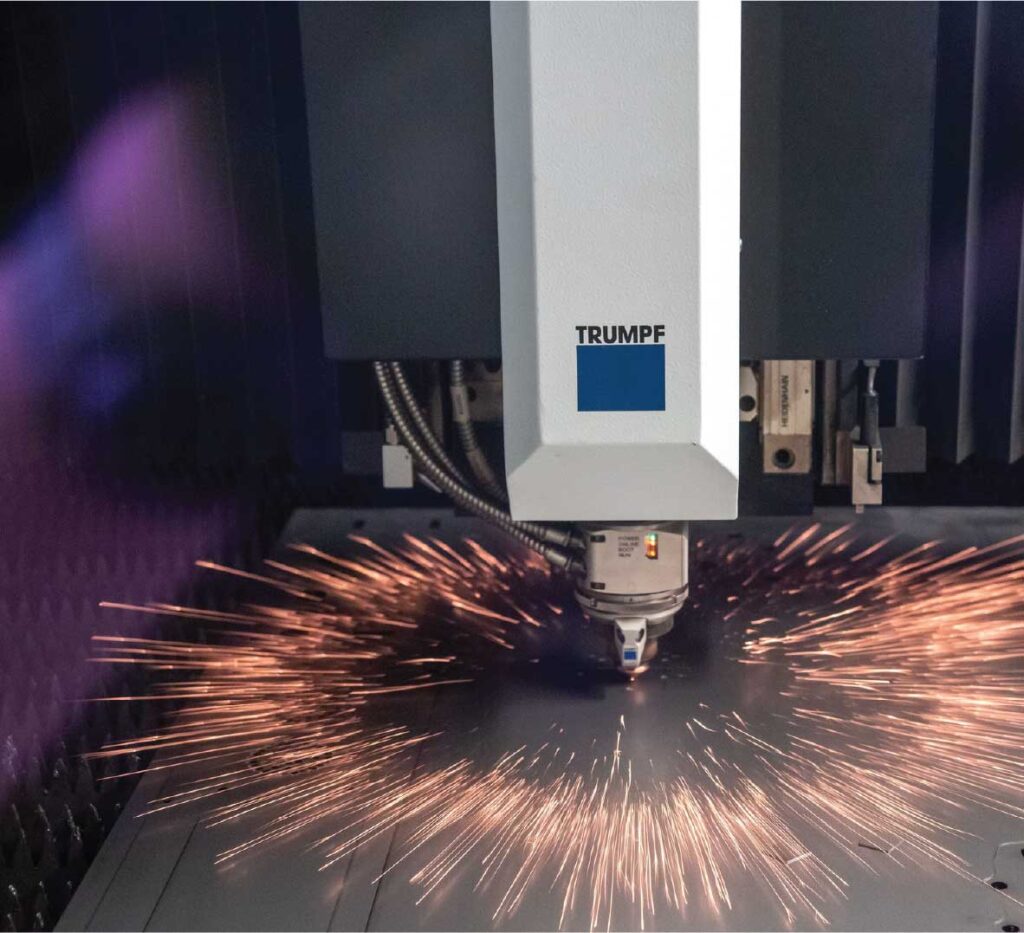

Fiber Laser Cutting

Our Trumpf 1030R Fiber-optic Laser provides high-production at low-cost.

CNC Punching

Our Trumpf 200R Linear Rail Punching provides an economical solution for back-end parts.

CNC Forming

Press Break Forming – 12ft capability, max .25 sheet thickness with standard tooling. Custom tooling may be available.

CNC Shearing

1/4′′ metal shearing at 10′ capacity.

Additional Services

- Hardware and PEM Installation

- Countersinking and Tapping

- Quick Turn Prototyping

- Rolling

- Laser Etching

Certified Welding

- Tig

- Mig

- Spot Welding

- Weld Assemblies and Frames

- Welding Repairs

Assembly

- We can assemble and package after completion.

Quality Assurance

- Quality Engineering Assistance

- CMM Inspection Services

- First Article and AQL Inspections

- Compliance and Document Control

Finishing

- Weld Grinding

- Surface Prep

- De-burring

- Tumbling

- Surface Graining

- Powder Coat, Anodize, & Plating- We have partnerships with quality 3rd party vendors for coating services.

Materials We Process

- Steel: .010 – 1.0 thickness

- Aluminum: .010 – .5 thickness

- Stainless: .010 – .5 thickness

- Brass

- Copper

- Titanium

About Welded Sheet Metal Manufacturing

75 Years of Quality!

Welded Sheet Metal Manufacturing LLC, formerly known as Welded Sheet Metal Specialty Company, is under new ownership. Our mission is to uphold the same reputation achieved over the last 75 years, and exceed those expectations by expanding our service offerings and remaining a reliable manufacturer for new and existing clients!

Why Us?

Servicing a wide variety of industries, WSM delivers timely and quality MTO fabrication services. From industries such as Commercial, Industrial, and Transportation, we have the manufacturing solutions for you!

By diversifying our service offerings, we can better serve the sustainability needs of our clients by developing an efficient manufacturing process. WSM strives to provide the best possible manufactured product while limiting waste and remaining cost-effective!

How do we do it? Our advanced technological approach and highly experienced team allows us to minimize client limitations. We can provide solutions, meet deadlines, and provide quality assurance!

Request a Quote